Designing Drones When Lives Are on the Line

A child is bitten by a snake. The hospital is three hours away. Could a drone pick up a vial of anti-venom and deliver it before it’s too late?

That is the kind of mission drones could one day handle. But only if we solve the complicated engineering behind payloads, stability, and reliability in real-world conditions

Your and My Incentive

My Proofs of Concept (POCs) train future tech leaders and answer “can it work?”

Follow along if you’re a drone enthusiast looking to enhance your tech skills to integrate drones better. In dBL (drone Based Learning) Every shaky hover taught what textbooks can’t. Every PID retune, failed landing, and dropped cargo teaches students. VIKAS isn’t a flashy demo drone. It’s a flying

lab where failures are turned into lessons.

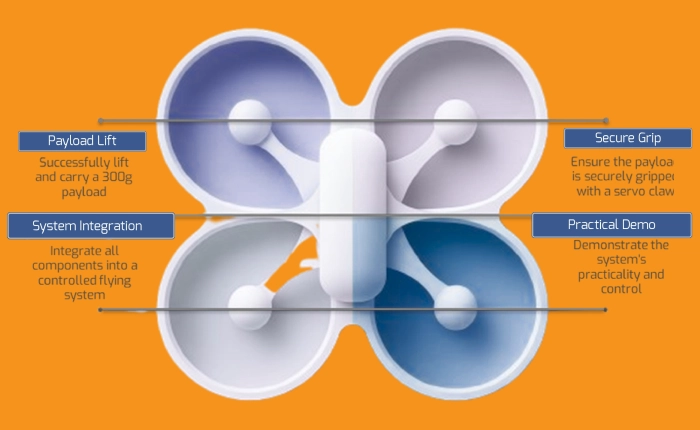

Designing drones when lives are on the line

We couldn’t complete the entire medical drone challenge in one shot. Instead, we aimed for a complete small-scale full system, showcasing:

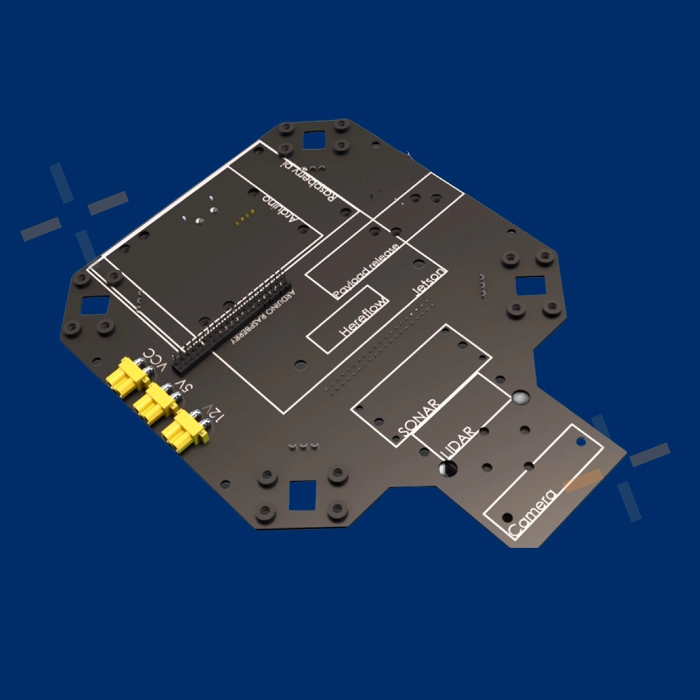

The Flying Testbench: Off-the-Shelf Meets Vishnu

Our setup was brutally simple by design:

- Gripper: Off-the-shelf servo claw, chosen for weight vs holding power.

- Latch: A 10g solenoid lock + 3D-printed bracket.

- Arduino as Companion: Running only gripper logic, so Pixhawk could focus on flight.

- Programming: MAVLink messages filtered to just what the Arduino needed (“open/close” + payload secure status).

- Lesson: Engineering is layer-based: You wire one system to fly, the other to control your add-on for just enough communication.

So Here’s a Sleek System Block Diagram

Safety Logic First,Code Second

On Arduino, we coded minimal safety logic:

- Don’t release unless latch sensor confirms “locked”

- Override: Pilot can cut power to the payload system (Arduino + Grip) mid-flight to drop in emergency

- MAVLink filter: accept only critical messages, ignore noise

This wasn’t “IoT cloud AI.” It was a microcontroller watching for one condition, one actuator, zero frills.

What Really Broke?

Dealing with real POCs here! Here are our real headaches and quick fixes:

Small hobby servos might become fatigued after 20 lock/unlock cycles, causing grip looseness.

- Solution: Use metal-gear servos or limit cycles to 15 with alarms.

- Battery penalty: Extra cargo and servo demand reduce flight endurance by ~40%. Solution: Upgrade to a 5000mAh 3S LiPo for ~15-18min endurance.

- Vibration Coupling: 3D-printed latch housing causes occasional misleading “locked” signals. Solution: Damping!

- Failures: At least two runs had premature cargo drop during descent due to latch slipping during vibration. Fix: Upgrade latch servo and filter vibration.

Can your ideas fly?

Whether it’s simulating crucial delivery missions, integrating a companion computer like Arduino, or experimenting with PID tuning, VIKAS keeps research grounded while allowing ambitious ideas to soar.